Is Back Painted Glass A Good Alternative For Ceramic Frit Glass In A Spandrel Application?

In this article we explore the benefits and limitations of Back Painted Glass and Ceramic Frit Glass used in an architectural spandrel application.

What is Back Painted Glass?

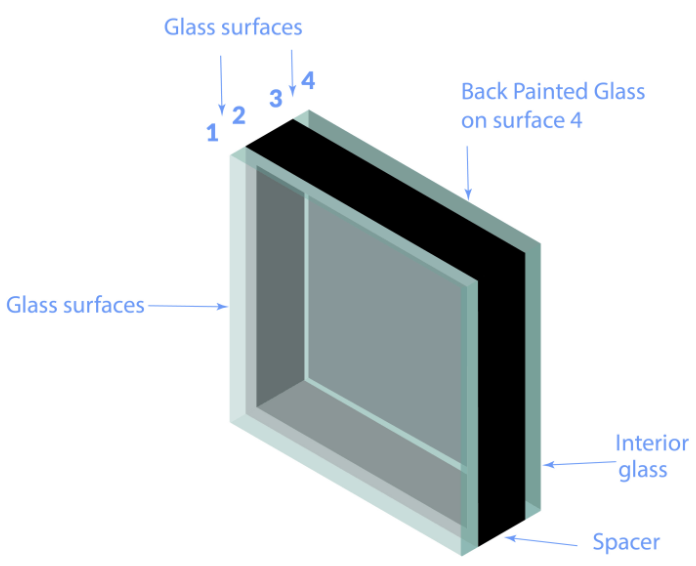

Back Painted Glass is any translucency of glass that has been painted on surface 2 on a single piece of spandrel glass or surface 4 of laminated or a sealed unit or back side of the glass. The viewing surface is surface one.

Spandrel Glass

Laminated

Spandrel Insulated Glass Unit

Creating Back Painted Glass is done using traditional solvent-based or solvent-borne coatings or alternatively water-based coatings, also known as water-borne glass coatings.

In spandrel applications, the painted coating must have a high level of opacity so that the spandrel area is not visible from surface one. The area behind the back painted glass must be void of light.

What is Ceramic Frit Glass?

Ceramic Frit Glass is created by fusing a ceramic-coloured enamel composition uniformly applied to a glass surface using temperatures of 950 to 1,100°C.

Ceramic Frit Glass is not to be confused with Frit Glass which is permeable to liquid or gas. Frit glass is used in laboratory applications as filters, spargers or scrubbers.

Where is Spandrel Glass used?

Spandrel glass is typically used to hide an area of a building that connects curtain walls or window walls to the building structure.

Spandrel Glass Application

What are the Benefits and Limitations of using Back Painted Glass in Spandrel Applications?

Back-painted glass products do not require expensive equipment to apply to glass. A low-cost HVLP spray gun is very effective for low to medium-volume back painting production.

The painted coating has very high adhesion characteristics to glazing sealants. The coating does not need to be removed or tapped off before installation of the spandrel glass which is a huge labour saving. However, OPACI-COAT-300 must have the coating removed or void around the spacer bar edge of a single unit or the contact edge of a single lite as the OPACI-COAT-300 is not compatible with most glazing sealants.

The coating is easily applied to the surface of the glass on Tempered or Laminated glass. In fact, our HC water-based coating can be applied to surface 3 of a laminated sheet before the glass is laminated.

Our HC water-based coating does not weaken the glass when cured (unlike the ceramic frit fusing process which can weaken the glass by 30%).

GPT’s HC water-based coating does not require expensive tempering equipment as it can ambient cure (unlike the ceramic frit fusing process)

GPT’s HC water-based coating will provide an even opaque finish when applied correctly. (unlike ceramic frit as outlined by Multiver Ltd ” Ceramic frit spandrel glass does not look perfectly even when exposed to light sources passing through both sides of the glass. For this reason, this product must always be placed in front of an opaque panel (like a wall cladding application) and not vision glass.”

Glass can be fabricated after painting unlike ceramic frit glass as it must be cut, shaped, polished and any holes drilled before ceramic frit is applied.

There is no limit to glass thickness with GPT’s coatings and no limit to the number of Custom Colors available which makes GPT’s coatings ideal for any decorative glass application.

What are the Benefits and Limitations of using Ceramic Frit Glass Panels in Spandrel Glass Applications?

Ceramic Enamel Frit coated glass can be created on existing tempering production lines.

Colours have almost no risk of delamination or cracking due to the fusion of the coloured enamels and glass under high heat.

Ceramic frit is non-toxic and non-combustible.

“Multiver ceramic frit paint is as strong as glass because they were fused together. There is no risk of scratching the ceramic frit coating during its manufacture, transportation, handling and installation.”

Ceramic frit glass can be created with digitally printed patterns and then fritted and is often used when bird-safe glass is required in Vision Areas.

The ceramic frit glass is used as vision panels to control or limit the amount of natural light entering a building which makes the interior environment more comfortable for building occupants.

Does the Ceramic Frit manufacturing process weaken glass?

A report written by Matt Bergers, Kayla Natividad, Stephen Morse and H. Scott Norville delivers test results relative to reduced glass strength once the glass received a ceramic frit coating:

“The authors tested five full scale samples of nominal 6 mm thick heat strengthened glass to failure under uniform lateral loading. One sample was clear glass, one sample had full coverage ceramic enamel frit, and the other three samples had ceramic enamel frit patterns with different percentages of coverage. In testing the samples with ceramic enamel frit applications, researchers oriented the specimens to place the ceramic enamel frit in tension under lateral loading. The authors found that the samples with ceramic enamel frit displayed considerably lower magnitudes of load resistance than did the clear heat strengthened sample. In addition, the authors noted that every fracture origin they have inspected to date from the 75 specimens with ceramic enamel frit patterns occurred underneath frit. Micrographs of fracture origins indicate that the frit may actually damage the glass surface during the heat strengthening process. This study has significant implications for architectural glass design.”

The report on Full-scale tests of heat-strengthened glass with ceramic frit is published here.